Shake, Rattle and Robot

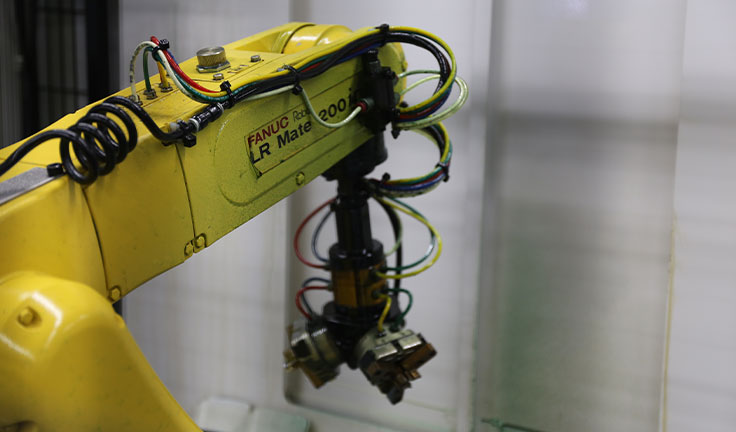

Combining vision technology with a surprise pop, we invested in the right equipment to keep Unity’s production moving swiftly for this client.

READ ONReal-life examples best illustrate our manufacturing capabilities. Every project is different, but a common thread weaving through everything we do: the Unity team goes above and beyond to innovate and deliver excellence.

Below are some of our favorite case studies. Each example provides a sense of our breadth, abilities, and process.

Combining vision technology with a surprise pop, we invested in the right equipment to keep Unity’s production moving swiftly for this client.

READ ON

A major medical customer had trusted another manufacturing company with their product, only to have problems with parts failing in the field, costing them roughly $5,000 per instance.

READ ON

Customers often come to Unity when they need help completing the processing on a particular part. We step in, fulfill that need, and get the customer’s pieces on their way.

READ ON

Sometimes the solution is right in front of you. When a three-part assembly proved unreliable, the Unity team returned to the drawing board to devise a better solution – while saving the customer both time and money.

READ ON

A hunting accessory supplier came to us with complaints about their current manufacturer. There were two problems: parts were not always late, and the supplier was not responsive to requests for information. Not the best relationship.

READ ON

A customer had several large medical instrument projects and was interested in adding a small project: five sizes of a single instrument, 2-3 times a year. Where more prominent manufacturers saw a small margin, we saw an ample opportunity to nurture a lasting relationship.

READ ON

For over 25 years, Unity Precision Manufacturing has been working with a medical device company that provides innovative, anatomy-conserving technologies for spine surgeons and their patients – and when we picked up another vendor’s slack, we strengthened our relationship for the long haul.

READ ON